In the fields of water supply and drainage engineering, gas transportation and trenchless construction, PE pipes are widely used due to their advantages of corrosion resistance, good flexibility and long service life. Among them, different types of PE pipes such as PE water supply pipes, PE drainage pipes, and PE drag pipes play an important role in various projects. The answer to the question of "whether PE pipes can be hot-melted" is yes. Hot-melt connection is a very reliable and commonly used connection method for PE pipes. The hot-melt connection of

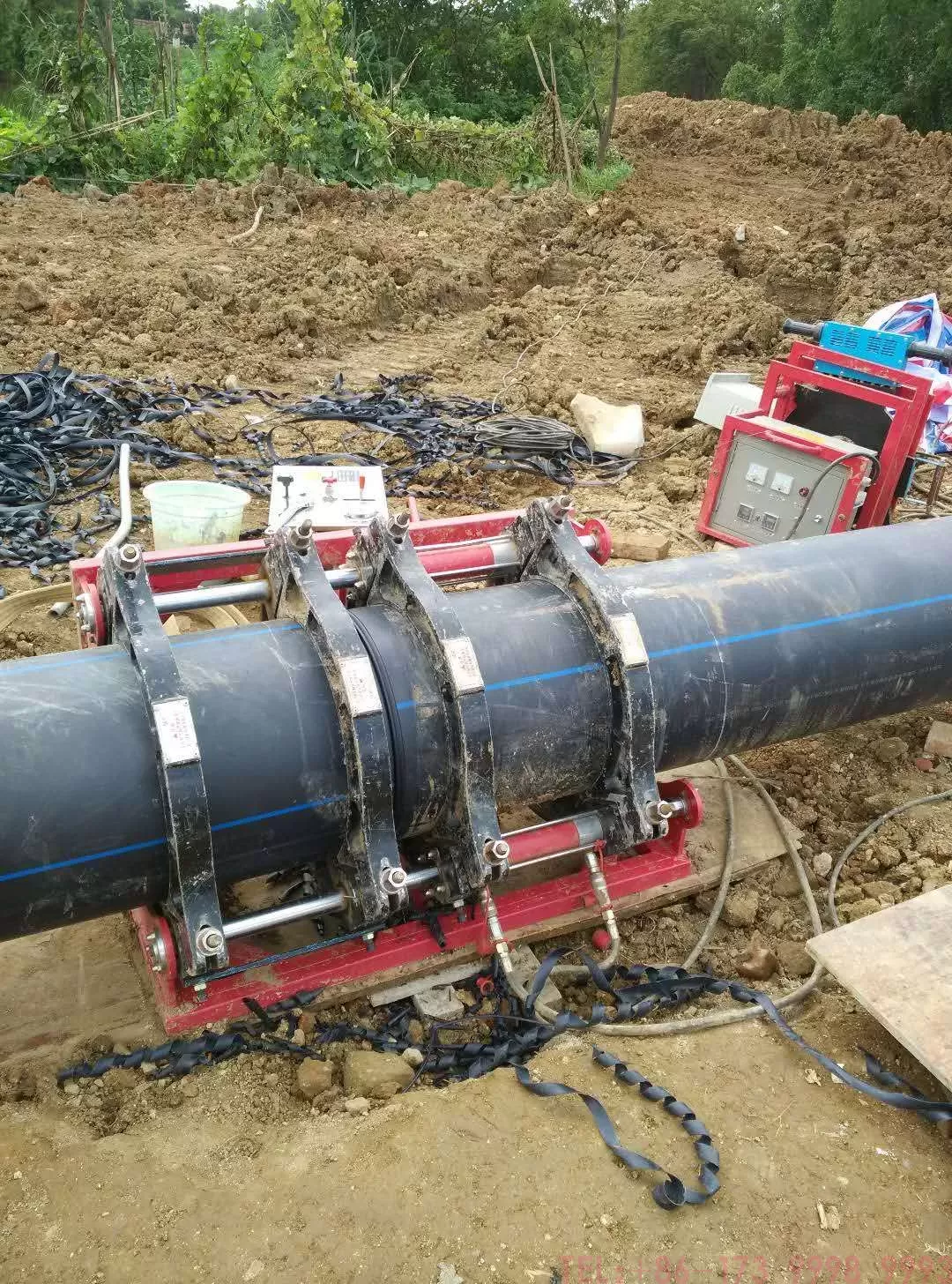

PE pipes is realized by special hot-melt equipment. During construction, the connection parts of PE pipes and pipe fittings are cleaned first to remove oil, dust and other impurities on the surface to ensure that the connection surface is clean. Subsequently, the heating plate of the hot melt equipment is heated to a specified temperature, generally between 210 ° C and 230 ° C. The specific temperature needs to be adjusted according to the material grade and wall thickness of the PE pipe. Then, the pipe and the pipe are smoothly pushed towards the heating plate, so that the connection parts are evenly heated. During the heating process, the end faces of the pipe and the pipe will gradually melt to form a uniform flanging. When the specified heating time is reached, quickly evacuate the heating plate, and quickly connect the pipe and the pipe, while applying a certain axial pressure to fully integrate the molten part. During the cooling process after the docking, keep the pipe and the pipe stationary, and wait for it to be completely cooled and shaped, then a strong hot melt connection is completed.

this hot melt connection method has significant advantages. First of all, the sealing is excellent, and the pipe and pipe fittings are integrated through hot melt, and there is almost no gap, which can effectively prevent liquid or gas leakage and ensure the tightness of the pipeline system. This is particularly important for PE water supply pipe drinking water transportation and gas transportation and other scenes with high sealing requirements. Secondly, the connection strength is high, and the interface strength after hot melt is even higher than that of the pipe itself, which can withstand greater pressure and tension. Even in complex geological conditions or long-term use, it is not easy to break the interface, which ensures the stability of PE drainage pipes and PE drag pipes in drainage and trenchless construction. Because of this, hot melt connections have been widely used in PE pipeline systems.

for engineering builders in Wuhan, Jingzhou, Jingmen, Qianjiang and other places, choosing high-quality PE pipes is the key to ensuring the quality of the project. As a professional PE pipe manufacturer, Hubei AD Building Materials Co., Ltd. has deeply cultivated the Hubei market and provided high-quality Hubei PE pipe products for the local area. The company's PE water supply pipes, PE drainage pipes, PE tractor pipes, etc., strictly follow national standards, and strive for excellence in every link from raw material purchase to production and processing, and then to finished product testing. Whether it is a small community pipeline renovation or a large-scale municipal project, Hubei AD Building Materials Co., Ltd. can meet the diverse needs of customers with rich experience and professional services. If you have relevant procurement or technical consultation needs, please call 17399989993, the company will provide you with professional solutions and high-quality products.

PE pipe can not only be hot-melted, but also hot-melt connection has become an ideal way for PE pipe system connection with its excellent performance. As a reliable PE pipe supplier, Hubei AD Building Materials Co., Ltd. will continue to provide solid product support for the engineering construction in Wuhan, Jingzhou, Jingmen, Qianjiang and other places, and help each project to advance smoothly.